Our auxiliary plants for security printing are compliant with Regulation 2006/42/CE and subsequent regulations concerning risk analysis.

We painstaking attention to detail, constant testing, quality certification (we are ISO 9001 certified since year 2000) and totally reliable service satisfy these requirements fully.

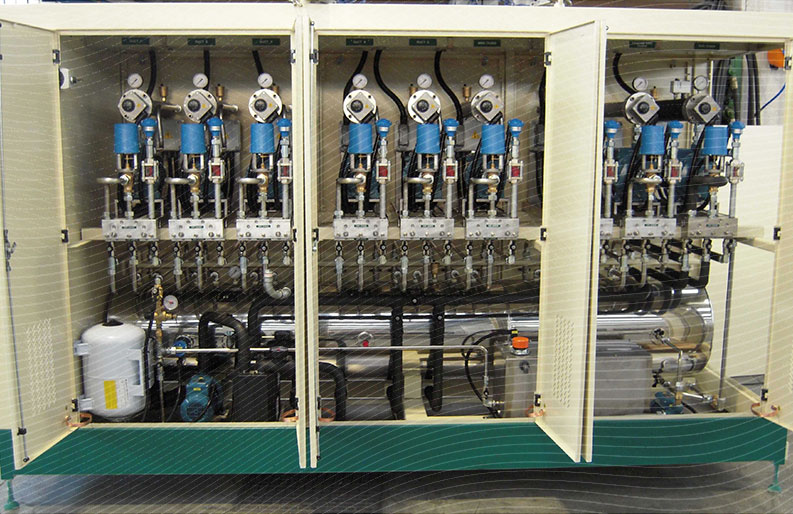

Thermoregulation units

UNIT FOR THE AUTOMATIC TEMPERATURE CONTROL

Compact unit for the automatic temperature control of reciprocating distributor rollers of the machine Super Orlof Intaglio 5 colours.

Temperature regulation units for security printing presses and water cooling plants are a strategic part of the security printing process, crucial for maintaining excellent quality levels.

Aqua Save II

WIPING SOLUTION PREPARATION, RECOVERY AND TREATMENT

This plant has been conceived for the preparation and recycling of the wiping solution required by intaglio printing machines, based on the latest generation of the recycling system superseding all ultra-filtration membranes recycling processes.

It has been developed to perfectly suit the printing machines by maintaining the characteristics of the wiping solution.

Galvanic plants for printing plates production

RAPID NICKEL PLATING BATH FOR 2 PLATES WITH ELECTRONIC RECTIFIER

Arranged for simultaneously growing two nickel printing plates.

Very latest improved model, with microprocessor controlled voltage increase, especially developed for the new sulphamate nickel bath “Speed”, with continuous filtration, two reciprocating cathode rods and bath agitation.

Sepotratt

TREATMENT OF THE GALVANIC WASTEWATER RESULTING FROM THE INTAGLIO PLATE MAKING DEPARTMENT (G)

PRE-TREATMENT OF WASTEWATER CONTAINING SOLVENTS (S)

TREATMENT OF POLYWASH WASTEWATER (P)

The plant is designed for treating the wastewater resulting from the following galvanic processes and relevant preparation and washing operations: Copper deposition, Nickel deposition, Chromium deposition, Electrolytic dechroming, Electrolytic degreasing, Chemical degreasing, Plate polishing, Offset plate making, Polymeric plate making.

We follow you through all phases, from designing and planning to manufacturing and installation.

All plants are fully mounted, tested, packed and stored in out workshop.