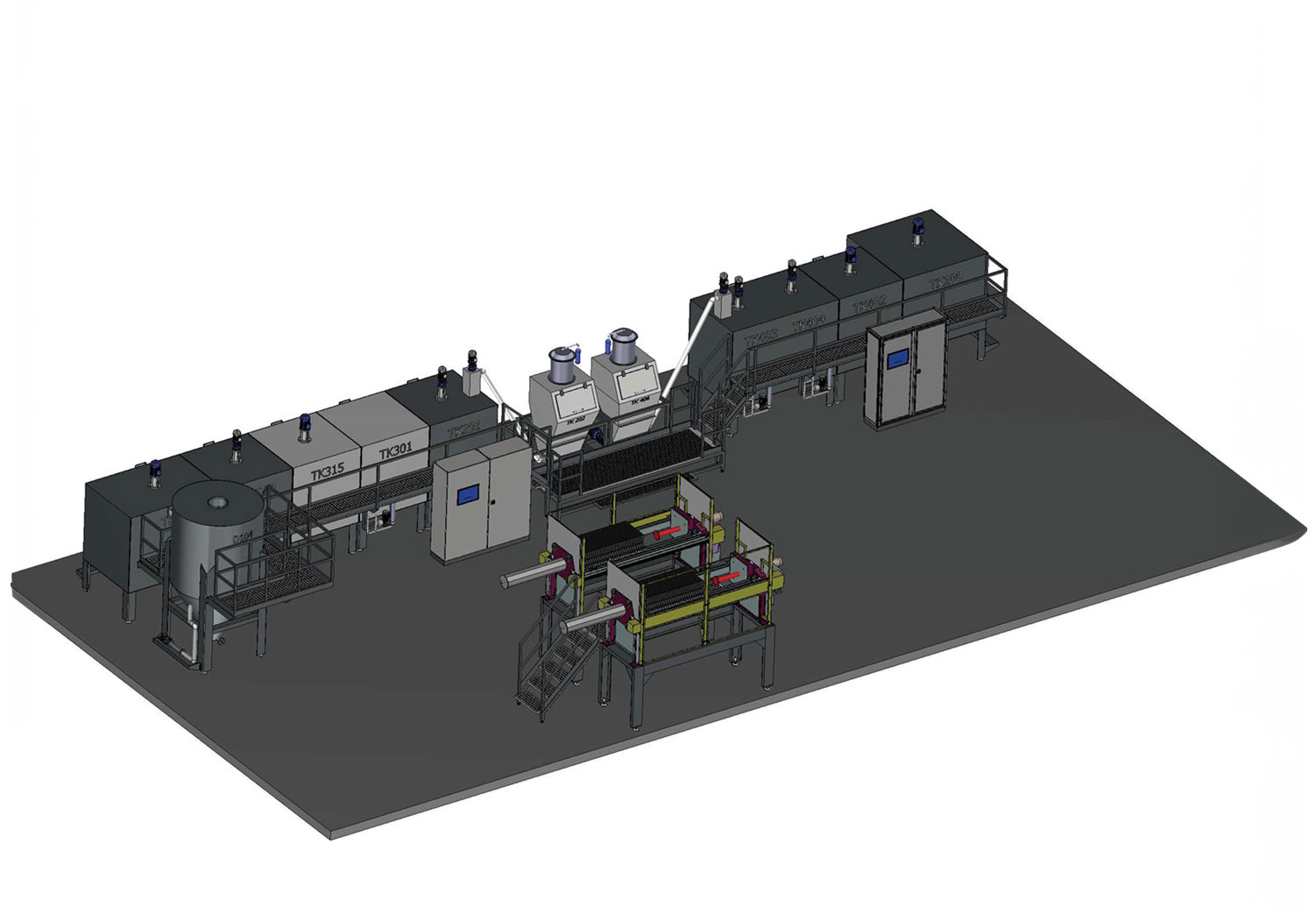

BASED ON LATEST GENERATION RECYCLING SYSTEM

This plant has been conceived for the preparation and recycling of the wiping solution required by intaglio printing machines.

It has been developed to perfectly suit the printing machines by maintaining the characteristics of the wiping solution. For many years this has resulted in excellent quality in banknote printing. The Aqua Save II DEC is the only system capable of achieving a recycling rate of more than 90% without modifying the standard wiping solution formulation and thus enabling to run the printing machine with a maximal efficiency.

Recycling is obtained by means of a chemical reagent, able to separate inks without modifying the characteristics of the wiping solution.

The separation of solids, in compact form and easy to handle, is carried out by static decantation and filter press system.

The performance of the installation is guaranteed with lowest energy consumption and running cost, also due to the elimination of the expensive ultra-filtration process and relevant replacement membranes.

The quality of the recycled solution obtained by the Aqua Save II DEC system is in accordance with recommendations, as it does not compromise the performance of the intaglio machine and its parts.

This recycling system permits to comply with all worldwide environmental regulations.

It has been conceived to overcome a few weaknesses relating to the ultrafiltration (UF) membranes and associated costs

- High recovery rate

- Very compact and dehydrated solid waste

- Very low consumption of chemicals

- Very reduced energy consumption

- Little request for maintenance and spares

- Good performance with any kind of ink

- Longer operating time for filter press for recovery, which will filter a solution already clarified

- Real-time production up to 3 shifts with no accumulation of used or recycled solution

- Process not affected by the presence of metallic pigments

- Independent treatment section for the small share of concentrate (<10%) in order not to affect the recycling section, also avoiding any accidental risk of chemical contamination of the recovered solution

- Possibility to treat in the independent treatment section also the waste solution occasionally accumulated in the emergency overflow tank.

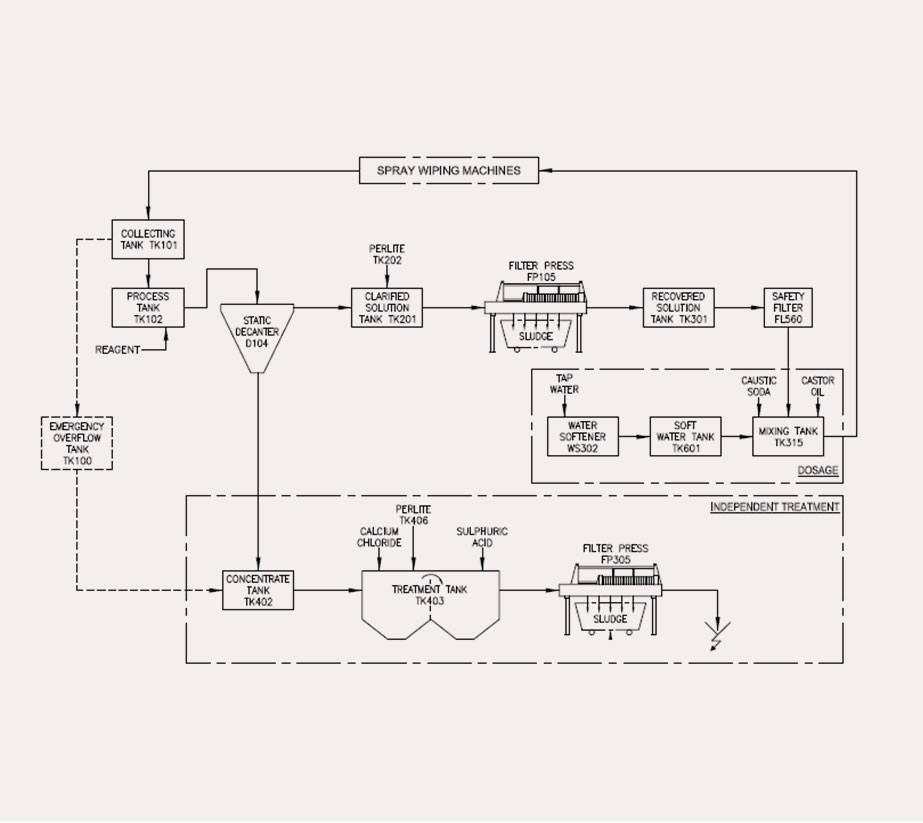

• The used solution coming from the wiping process on the intaglio machines equipped with spray wiping system is at first stored in the collecting tank TK101; an emergency overflow tank is to be provided locally.

• The used solution is pumped to the process tank TK102, where also the reagent Dalsep is proportionally added.

• The processed effluent is pumped to the static decanter D104, from which the supernatant gradually overflows to the clarified solution tank TK201, while the concentrate is pumped to the storage tank TK402 of the independent treatment section.

• A very small quantity of filter-aid Perlite is proportionally added in the clarified solution tank TK201, via the automatic dosing device TK202, before the supernatant is sent to the filter press FP205 to eliminate any residual traces of particles.

• Once reached a proper pressure inside, corresponding to the end of cycle, the filter has to be opened for solid waste removal, while the liquid is transferred to the recovered solution storage tank TK301 and then to the wiping solution preparation tank TK315 through a safety cartridges’ filter FT560.

• Slight integrations of wiping solution ingredients are automatically provided in the mixing tank by soft water from water softener WS302 and storage tank TK601 as well as caustic soda solution and castor oil from… corresponding dosing lines.

• After automatic correction and heating, the wiping solution is pumped to the intaglio machines.

• The share of concentrate in the bottom part of the decanter is automatically pumped to the storage tank TK402 of the independent treatment section.

• The concentrate is then transferred to the treatment tank TK403, where the calcium chloride and sulphuric acid are automatically dosed, together with a small amount of perlite via the dosing device TK406, before filtration in the filter press FP405.

• The treated effluent is then drained (or sent to an evaporation stage – option)

• Whenever needed, also the used solution occasionally contained in the emergency overflow tank can be treated in the treatment section of the plant, as above described.

- Collection of used solution

- Ink separation

- Filtration and storage of recovered solution

- Wiping solution production

- Wiping solution correction

- Independent treatment section